🤖💡 Making Remote Robot Software Updates a Breeze: Discover the Power of ROS Toolbox & Automated Tools

In the dynamic world of robotics, ensuring that your robots operate with the latest software is a cornerstone of operational success. However, the task of remotely updating software on robots can be complex and time-consuming. This is where the ROS Toolbox and automated code generation tools come into play, streamlining the update process and enhancing efficiency. In this blog post, we’ll explore how these technologies transform the remote software update experience, making it more manageable and reliable for developers and operators alike.

Manual Updates: Imagine trying to update your robot’s software manually. Each robot may have its own set of requirements and dependencies, which makes the process time-consuming and prone to errors. This complexity underscores the necessity for an automated solution that can streamline the update process, ensuring consistency and efficiency without the manual overhead.

Automated Updates: Transitioning from manual to automated updates is akin to upgrading from a manual assembly line to a sophisticated, synchronized automation system. In this system, each robot, with its distinct characteristics and functions, receives precisely the updates it needs at the exact moment required. An automated system adeptly manages this complexity with the precision and consistency necessary for such a task.

To address the challenge of coordinating updates across a diverse fleet of robots, a specialized set of tools is essential. These tools must meet several critical requirements to facilitate automated deployment to remote robots. Atomic updates are vital—they ensure that each update is applied completely or not at all, thereby maintaining system stability. Customizing configurations for individual robots is also imperative, as it accounts for the unique attributes and needs of each machine. Additionally, the ability to debug directly on the device is a game-changer, as it accelerates the process of identifying and resolving issues.

Together, these elements constitute the backbone of a powerful and streamlined automated deployment system. Such a system is designed to deliver smooth and effective software updates, enhancing the performance of remote robotic devices without the complexities of manual intervention.

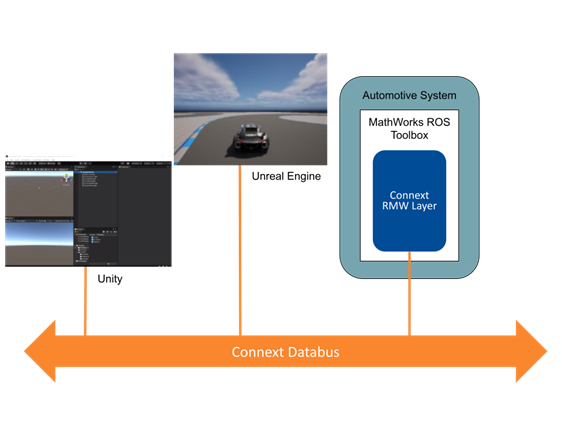

ROS: In the land of robot communication, ROS, particularly ROS 2, marked a significant technical breakthrough. It’s got better ways to chat over networks, keep secrets safe, and use DDS – a magical language that helps robots share their thoughts more efficiently. It ensures reliable and secure communication between robotic components, making it well-suited for applications requiring stable network connections and adherence to industry standards. The adoption of DDS enhances data distribution efficiency, contributing to ROS 2’s reputation as a robust and secure framework for advanced robotic systems.

Overcoming Technical Hurdles: Yet, the road wasn’t smooth. We faced some tough challenges. Dealing with different types of robot hardware, figuring out testing details, and staying a step ahead of unexpected issues were all part of the journey. Each robot, with its own unique hardware, brought its own set of issues. Testing turned into a careful dance, making sure everything worked well on all types of robots. We had to use thorough testing methods to make sure the solutions we deployed were reliable.

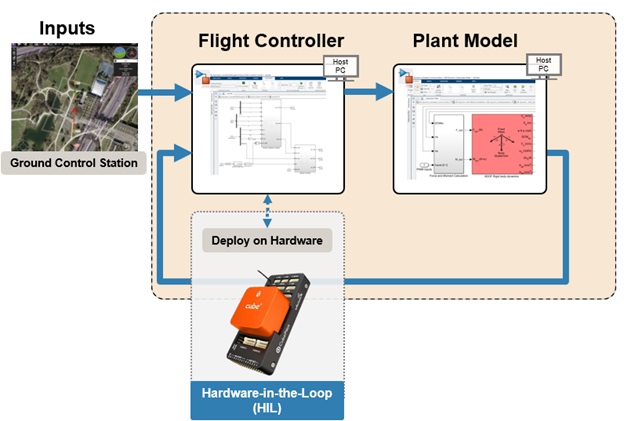

MATLAB and Simulink in Action: The journey from concept design to production implementation and deployment has never been easier. MATLAB and Simulink became integral components, providing a unified platform for algorithm development and streamlined deployment.

MATLAB and Simulink emerged as the principal tools, providing a robust platform for the entire development lifecycle. These platforms streamlined the transition from concept design to production implementation and deployment. The intricate process of algorithm development, system simulation, and code deployment converged seamlessly, fostering an environment of technical precision.

And here’s the kicker: with ROS Toolbox and MATLAB, you don’t need to be a wizard in CMake or a guru in C++. Nope, you can leave those books on the shelf! MATLAB lets you create ROS packages without diving into those deep, dark coding languages. It’s like having a magic wand that does the heavy lifting for you.

Efficient ROS Deployment: The ROS Toolbox provides a seamless integration with MATLAB and Simulink, offering a powerful and efficient means of deploying ROS packages to remote robotic hardware. The process of configuring software models for deployment is greatly simplified, enabling users to define ROS-based software models that include customizable options for handling complex data structures like variable-sized arrays and managing dependencies on external ROS packages.

When it comes to deployment, the ROS Toolbox facilitates a smooth operation. Users first configure the connection to the remote ROS-enabled device, which is typically any Linux system equipped with ROS and capable of building and executing a ROS node. The toolbox then takes over, automating the transfer of generated code to the remote device, compiling it into an executable, and launching the ROS node. This turns the daunting task of sending updates to robots in remote locations into a precise and systematic process. The efficiency and adaptability that ROS Toolbox introduces to the deployment process are transformative. It not only simplifies the steps involved but also ensures that the deployed solutions are finely tuned to meet the diverse operational needs of different robotic platforms.

Streamlining Debugging: Debugging on a remote robot in real-time presented its own set of challenges. However, ROS Toolbox transformed this complexity into a systematic process. Once deployed, ROS Toolbox facilitates real-time tuning and visualization through various methods, including the use of ROS device objects, configuring nodes through ROS parameter servers, and leveraging Simulink’s external mode. External mode establishes a communication channel between Simulink on the host computer and the target hardware, enabling users to modify block parameters, monitor and save signal data, and retrieve execution-time metrics for debugging. The capability to tune parameters and monitor signals in real-time underscores the versatility and effectiveness of ROS Toolbox in addressing the evolving demands of robotic applications.

In conclusion, this journey from deployment challenges to ROS brilliance with MATLAB and Simulink has redefined the future of robotics. The integration of these powerful tools offers efficiency, precision, and innovation in the field. The complex process of development, testing, and deployment has been replaced by a well-orchestrated symphony of technological advancements.

We invite you to dive deeper into this realm of possibilities, explore the trial version of MATLAB, watch our detailed webinar video, and unlock the potential of automation in robotic technology. As the horizon of robotics expands, the combination of ROS, MATLAB, and Simulink stands as a testament to the limitless possibilities that await in the automated deployment landscape.

コメント

コメントを残すには、ここ をクリックして MathWorks アカウントにサインインするか新しい MathWorks アカウントを作成します。