Startup Spotlight: weg//weiser GmbH Aims to Streamline Electric Motor Testing

Perhaps some of the best ideas emerge from a simple dinner with friends. And when these ideas lead to a company focused on finding a solution for its own needs, but also for those within major industries, it’s bound to be an outcome of success.

This is the backstory behind the startup company weg//weiser. While working in a laboratory focusing on drive technology, some friends, Christian Klöffer and Philipp Degel, faced a consistent problem. “Testing new motors without the necessary information was always a major headache,” recalls Philipp Degel, CEO of weg//weiser. “We started looking into the possibility of automatically measuring electric motors, and eventually decided to build a company around solving this problem.” The years of pain were inspiration to come up with a solution for fellow engineers.

Electric vehicles (EVs) have become a backbone of the energy transition. The core of every EV is a complex electric motor. Getting these motors from the lab to the road is a challenging process. For engineers, testing and commissioning new motor designs can be a time-consuming, costly, and expertise-heavy process. Weg//weiser aims to change that with a system that automates and accelerates electric motor characterization, delivering test results faster with exceptional performance.

The Problem: Electric Motor Testing is Slow, Expensive, and Complex

The global shift to electromobility is reshaping how people and goods are moved. As new types of electric machines are developed, testing and measuring of these motors’ performance remains a critical bottleneck. Information is required to set operating points for certain conditions, such as the torque to be achieved under a specific speed, voltage, and temperature. This leads to the question of how the necessary complex information should be obtained. Companies are suddenly confronted with new, highly technical tasks.

The current situation is usually such that internally developed solutions have to be constantly modified and adapted to new requirements, or are underutilized. A lack of automation and complex integration increases the time required for commissioning, leading to slower innovation and rising costs for the use of expensive laboratories over a longer period of time

The Solution: weg//weiser’s Automated Universal Motor Test System

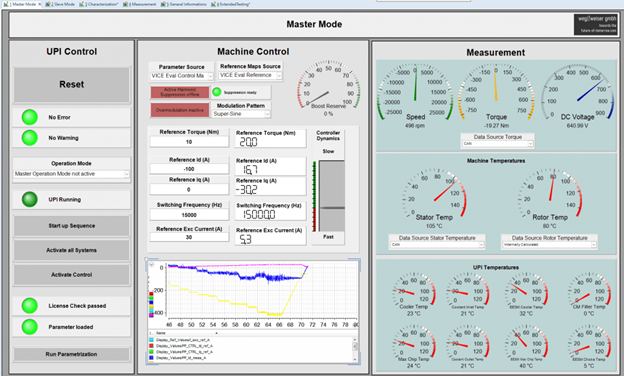

Weg//weiser’s solution is a universal test system for all types of electric motors. The software provides a fully automated evaluation of all measurement data across the entire speed range, deriving all relevant control parameters for optimal and safe motor operation. The flexible environment can be integrated into existing testbed systems, while allowing for customer-specific adaptations to meet tailored process solutions and expandable to future needs.

“Our mission is to empower our customers to complete their tests in record time with exceptional performance,” says Degel. “We want anyone to operate and analyze any electrical machine without needing expert-level knowledge.” To face testing complexity for operators, the platform incorporates a simple interface with “one-click” for commissioning, characterization, and evaluation of electric machines.

As Degel puts it, “Automated measurement routines, combined with detailed data evaluation, achieve the commissioning of electric motors in the shortest time possible.” This approach saves customers significant time and money when bringing new products to market, while delivering reliable, repeatable results.

weg//weiser’s operator interface for testing and commissioning of engines. (Image courtesy of weg//weiser)

Accelerating Innovation with MATLAB

A key part of weg//weiser’s rapid development of their platform was integrating MATLAB into their engineering foundation. “As an engineer, you often have the false perception that you could solve the problem better yourself. You must learn that nobody pays you money to reinvent the wheel,” says Degel. “MATLAB gives us the opportunity to focus our energy and time on innovation.”

The company developed sophisticated algorithms for evaluating measurement data in real-time with MATLAB and Simulink. To streamline the transition from development to deployment, weg//weiser uses Simulink Coder to generate code for their dSPACE system. Finally, the team leverages MATLAB Compiler to create a front-end for their parameterization and data evaluation tools. Stateflow automates even the most complex test routines.

Degel points out that using MATLAB and Simulink enabled weg//weiser to deliver their new platform to market faster and with reduced R&D costs by an estimated 50%. He adds, “Thanks to MathWorks tools, we as a small company can still develop very quickly and generate a high output of innovation. As we must be technically on a par with global corporations, this is one of the keys to the [startup] company’s success.”

Lessons for Founders

Weg//weiser’s journey hasn’t been without unique challenges. As an engineer turned CEO, Degel realizes the need to keep the overall product and customer in mind without getting lost in the technical details of the solution. His advice for other founders comes from his own experience. “Never stop learning and always meet people with an open mind. Treating customers with respect and trust is the most important thing. If the customer knows they can rely on us, you build long-term and reliable business relationships,” concludes Degel.

By making electric motor testing faster, easier, and more accessible, weg//weiser is helping drive the future of electromobility.

Learn more about weg//weiser: https://future-of-tomorrow.com/

Learn more about MathWorks Startup Program: https://www.mathworks.com/products/startups.html

- カテゴリ:

- Startup Spotlights

コメント

コメントを残すには、ここ をクリックして MathWorks アカウントにサインインするか新しい MathWorks アカウントを作成します。