Startup Shorts: Reflex Aerospace Delivers Custom Satellites at Next Generation Speed

Three. Two. One. A silent room of engineers crowds around a screen, intently watching as their hard work takes flight on board the Falcon 9 of SpaceX. Minutes later, the room erupted in a sudden burst of cheers, hugs, and pride. This was the scene during the inaugural launch of SIGI, Reflex Aerospace’s first satellite.

For startup Reflex Aerospace, the successful launch secured its place in the “New Space” era. It was the first step to proving that satellites can be designed, built, and deployed in under 12 months, all without sacrificing quality or reliability.

Speed Matters in Space

For decades, satellite development has meant long lead times, massive budgets, and little room for iteration. “The old space approach was to build satellites capable of achieving lifetimes of 10 to 15 years, but that’s not needed anymore,” explains Gabriele Palumbo, Altitude and Orbit Control System (AOCS) Engineer at Reflex Aerospace.

Space technology is moving rapidly. What’s cutting-edge today could be obsolete in two to three years. This urgency is driven by the rapid evolution of payloads, including cameras, sensors, and communication systems that are installed on satellites. Levi Vuylsteke, Lead Altitude and Orbit Control System (AOCS) Engineer at Reflex Aerospace, draws an analogy to how technology improves so rapidly in smartphones: “It’s the same thing with satellites. If you have a lead time of more than four years, it doesn’t make sense. The market craves fast satellites.”

Over the past two decades, the CubeSat approach has revolutionized, in part, the design of satellites. Makers use off-the-shelf components to reduce delivery times. However, the market was wary about the lack of reliability and performance with these platforms.

Reflex is on a mission to deliver highly reliable custom satellites at a pace that matches the rapid evolution of technology on Earth. At its core, Reflex is driven by the belief that the old way of doing things no longer meets the needs of today’s space industry.

A New Approach to Satellite Development

Reflex’s approach to satellite development is fundamentally different than previous generations. They blend the best of both practices: the reliability and customization of traditional “Old Space” with the agility and speed of “New Space.”

“We design a platform that is custom-made for the customer, but we generalize our processes to streamline system design,” Palumbo notes. The team is not constrained by a particular supplier. They source components, even from outside the traditional space supply chain, if it means faster delivery and equal or better reliability. This flexibility extends to manufacturing. Reflex designs satellites to be fast to build and integrate, shortening procurement and assembly times. The result: satellites tailored to mission needs, delivered on timelines that keep pace with technological change.

The ability to deliver satellites quickly is not just a technical achievement for the builder but also advantageous for its customers. Satellite constellations are becoming the norm. Instead of relying on a single, long-lived satellite, operators deploy fleets of smaller satellites that can be refreshed every few years. This approach keeps their services at the highest level, allowing them to adapt to changing market demands.

Simulation at the Core

Central to Reflex’s speed and reliability is its commitment to simulation-driven development. “You only have one try in space. You can’t launch these satellites and have them fail,” Vuylsteke says. “Simulations are very important. We use them across all phases of satellite development.”

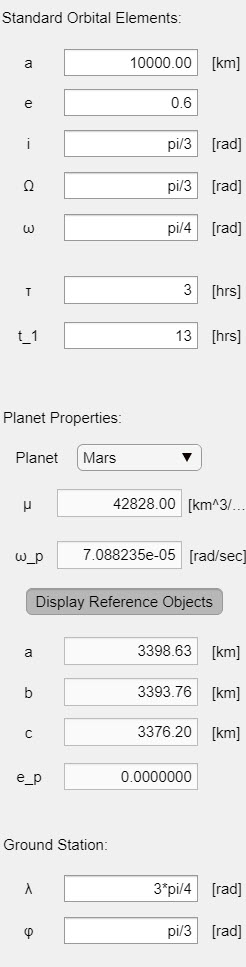

The workflow begins with system-level modeling in Simulink, where engineers build digital twins of their satellites. “For our AOCS simulator, we use the MATLAB and Simulink toolchain,” shares Vuylsteke. “It allows us to rapidly develop the simulator, and we benefit from predefined Simulink blocks.”

To accurately represent the space environment and satellite dynamics, Reflex leverages the Aerospace Toolbox and Aerospace Blockset. These toolboxes provide ready-to-use models for orbit propagation, attitude dynamics, and environmental effects such as Earth’s magnetic field.

Stateflow is used to map out the satellite’s operational modes so that every transition and contingency is accounted for. The environment lets them experiment, iterate, and refine designs before any hardware is built. The team leverages Parallel Computing Toolbox to accelerate large-scale simulation campaigns, efficiently exploring thousands of scenarios. As the design matures, Simulink Coder is used to automatically generate C-code, ensuring a seamless transition from model to onboard software.

“The startup license let us experiment with different toolboxes and see what fits our workflow. The support from MathWorks has been invaluable; feature requests, bug fixes, and training resources have all helped us push the boundaries.” – Levi Vuylsteke, Lead Altitude and Orbit Control System (AOCS) Engineer at Reflex Aerospace

Despite their rapid pace, Reflex does not cut corners on verification and validation. “Testing is very important. You have to test early and often,” Vuylsteke emphasizes. The team employs a layered approach to testing, starting with unit tests for every low-level function to system-level functional testing with Simulink Test. Monte Carlo simulations are run to probe the robustness of control algorithms against uncertainties.

Once the software passes the virtual checks, Reflex moves to processor-in-the-loop and hardware-in-the-loop testing. This ensures their satellite will behave exactly as intended when it reaches orbit. “We make sure our generated code behaves the same as in the simulations,” Vuylsteke says. “It’s very satisfying as an engineer to see that your simulation matches reality perfectly.”

Requirements-based test cases are formulated early and reused throughout development, helping catch errors before they reach the hardware stage. As Palumbo explains, “We use Simulink testing capabilities to validate our core libraries and blocks. With every new mission, we start from our heritage, adapt, and revalidate.” With the satellite in space, Curve Fitting Toolbox supports data analysis and post-processing, helping engineers validate that real-world performance matches their predictions.

By weaving these toolboxes into a seamless digital workflow, Reflex Aerospace can adapt to changing requirements and deliver satellites faster than previous generations. The rigorous V&V workflow maintained by Reflex Aerospace ensures that satellites not only launch quickly but also perform reliably in the demanding environment.

Looking Ahead from Launch

The culmination of this development process was the launch of SIGI, Reflex’s first satellite. The whole team was on hand to watch the SpaceX live stream. When SIGI separated from the rocket, the engineers rushed to the mission operations room to see the first data roll in. Vuylsteke recalls, “It was one of the most stressful and exciting moments of my life.”

With SIGI in orbit, Reflex is already looking ahead. “Now that we have a real satellite in space, we can use that data to validate and improve our simulation models,” Vuylsteke concludes. “Our simulations are generic, so we can quickly adapt them for new missions. We’re building modular architectures and libraries of blocks, making it easy to swap components and scale up production.”

Reflex Aerospace aims to democratize access to space. By reducing costs and timelines, they enable organizations, including governments, research institutions, and commercial ventures, to deploy satellites tailored to their specific needs. This has far-reaching potential from new scientific discoveries to improved global communications.

The startup is setting a new standard for the industry. By proving that high-quality satellites can be delivered quickly and reliably, Reflex is challenging legacy builders to rethink their own processes and embrace innovation.

Hear more from the Reflex Aerospace team:

Learn more about Reflex Aerospace: https://www.reflexaerospace.com/

Learn more about MathWorks Startup Program: https://www.mathworks.com/products/startups.html

댓글

댓글을 남기려면 링크 를 클릭하여 MathWorks 계정에 로그인하거나 계정을 새로 만드십시오.