“Faster than a Speeding Bullet” takes on new meaning with this all-electric car

Engineering students from the Ohio State University Center for Automotive Research (CAR) recently set a world record with their all-electric vehicle. While this is a tremendous achievement, this was far from a first for the CAR engineers: This was their fifth world record.

The students and faculty at CAR, with corporate sponsor Monaco-based Venturi Automobiles, spent six years updating and perfecting their design for the Venturi Buckeye Bullet 3 (VBB-3). This streamlined vehicle went through a radical redesign from the previous VBB version, enabling it to set a new land speed record (LSR) of 341 miles per hour (548km/h) at the Bonneville Salt Flats in Utah in September.

As reported by Fox Sports, this beat the previous record of 307 mph the same team had set with an earlier version of the VBB in 2010. According to CNN, the VBB-3 “recorded a top speed of 358 mph, propelled by a 3,000-horsepower engine that Venturi says makes it the world’s most powerful electric car.”

How the LSR is determined

The record was confirmed by the Fédération Internationale de l’Automobile (FIA). The FIA considers the speed recorded in the middle mile of an eleven-mile run. The record is based on the average time for two runs in opposite directions on the same track. These runs must be completed within one hour of each other.

The VBB-3

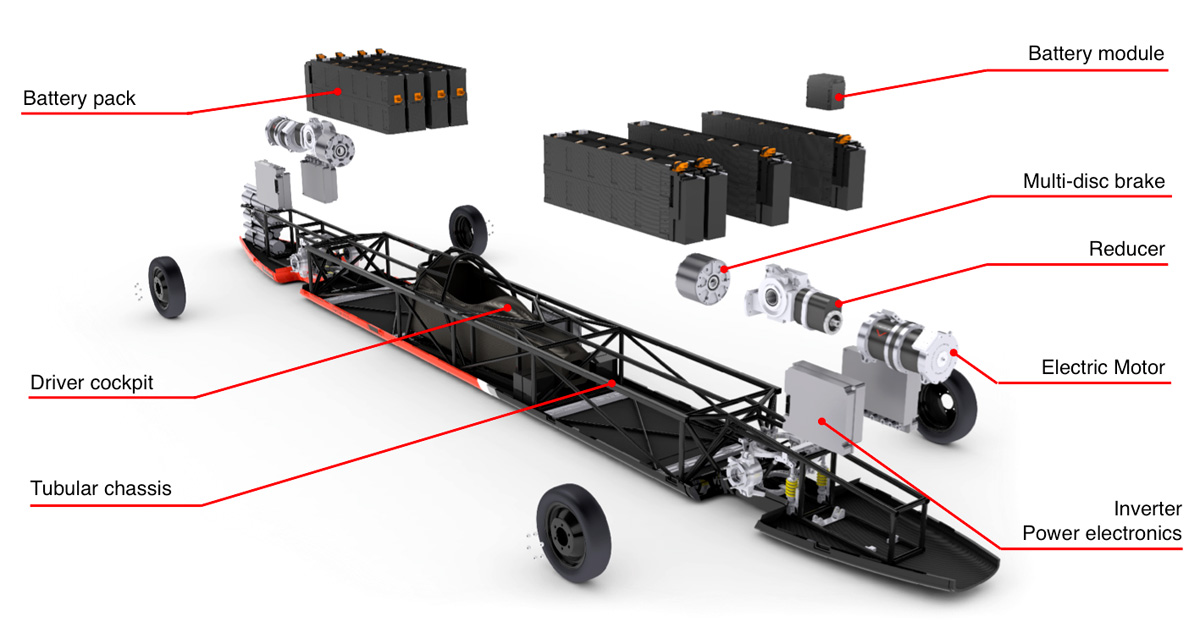

The record-setting VBB-3 is propelled by two custom electric motors, powered by over two megawatts of lithium-ion batteries. It is an all-electric vehicle, and in this iteration of the design, the team switched to a 4-wheel drive version. The car is 11.3 meters long and weighs 7,700 pounds. The car has a drag coefficient of only 0.13, much less than the 0.30 to 0.35 drag coefficient for a typical production car.

Getting the design right

How do you design a 3,000 horsepower all-electric car that is shaped like an airplane fuselage and requires 3,500 pounds of lithium-ion batteries? The team from Ohio State started with simulation. Model-Based Design has been critical for the design and execution of the Buckeye Bullet. The Buckeye Bullet project used MATLAB and Simulink for system-level modeling to design the earliest version of the VBB and has continued to use this approach to improve the design throughout the VBB program.

After the 2010 record-setting run, the team revamped the design and built the VBB-3 vehicle from the ground up, spending nearly two years running simulations and refining component-level design before creating the physical prototype. The changes were significant: The 2010 VBB-2.5 weighed 0.4 tons to the VBB-3’s 1.6 tons. The horsepower was increased from 800 to 3,000, and the total torque increased over 500% to 2,800 Nm.

Modeling and simulation

Since the VBB-3 project began in 2011, modeling and simulation played a key role in the design and development of the vehicle. A vehicle simulator was created in Simulink. It enabled the team to quickly understand and optimize parameters such as:

- 2-wheel drive versus 4-wheel drive

- The number of battery packs needed

- The number of gears and which gear ratios to use in the transmission

- Vehicle dynamics including weight transfer, aerodynamics, and rolling resistance

The ultimate goal of the simulations was to estimate potential vehicle speeds for the new vehicle.

“Many important decisions were made in the construction of the VBB-3 based on our ability to perform preliminary simulations,” stated Ross Johnstal, engineering student and electrical team leader on the VBB-3 project. “Going forward, the team will be paying close attention to gear ratios so that we can maximize acceleration on the shorter than desired track lengths at the Bonneville Salt Flats in future runs.”

Data processing and analysis

The ability to quickly process and analyze recorded vehicle data is critical. Gigabytes of data are collected every time the sensor-laden car completes a test run. “Whether it’s data from lower speed runs at the test track or high speed runs out in Utah, we need to convert, review and visualize all of the data we capture from dozens of sensors throughout the car,” stated Johnstal.

MATLAB scripts pull millions of data points which are then calibrated and resampled to obtain a uniform time scale to aid in the analysis of the data. After this process, plots are generated and automatically consolidated into a report.

Vehicle control code development

The vehicle’s main engine control unit (ECU) is an ETAS prototyping unit. The ECU code is generated from the team’s Simulink/Stateflow models.

“The ability to program the car using Model-Based Design allows the team to rapidly and confidently develop the vehicle’s control system,” says Johnstal.

Automated vehicle battery charging

The team also developed a script to create a Controller Area Network (CAN bus) communication bridge between the vehicle and the 250kW battery charger. In order to automate the vehicle charging process, a communication link needed to be established between the vehicle and the charger. The Vehicle Network Toolbox was used to accomplish this with its native CAN bus capabilities.

“Our vehicle is CAN enabled and our battery charger has CAN capabilities. The main problem was that all of our CAN buses in the vehicle run at speeds of 500kbps or 1Mbps, while the charger required the use of a 250kbps bus,” said Johnstal. “We developed a semi-real-time script to link the vehicle to the charger even though they both operate on different CAN speeds. This tool allowed the vehicle to quickly charge itself.”

Next up: 400 mph

The Bullet team isn’t quite done. According to student team leader Michael Johanni, “We set out with the goal to do 400mph and we’d still like to achieve that. Based on an initial review of our data from Bonneville, the numbers are reassuring. The potential acceleration and top speed are there, if we do some tweaking and find the right course to race on.”

“Today, now that we have collected our best ever high-speed run data from this past September, the team plans to compare the results with our past simulations to our real run data and adjust and optimize the simulator so that we can learn how to maximize the opportunity for the VBB3 to reach faster speeds,” stated Johnstal.

This car accelerated from 0 to 358 mph in just over 100 seconds. Pretty amazing. Even more amazing when you consider the Ohio State team is comprised solely of volunteers. The team members range from high school interns to graduate students. “There is no class credit. It’s not a part of the curriculum at all,” said Johanni.

The video below shows the VBB-3 in action.

Follow the VBB team on Twitter with #VBB3 as it pursues the goal of surpassing the 400 mph goal in the next test run.

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.