This post is from Ajit Jaokar. Based in London, Ajit's work spans research, entrepreneurship and academia relating to artificial intelligence (AI) and the internet of things (IoT). Ajit works as a data scientist through his company Feynlabs - focusing on building innovative early stage AI prototypes for domains such as cybersecurity, robotics and healthcare. He is the course director of the course: Artificial Intelligence: Cloud and Edge Implementations.

Introduction

We are going to talk about the

Digital Twins course that is being offered by the University of Oxford Department of Continuing Education and is based on MATLAB and Unity. Learners will study model-based design under the framework of the

digital twin and its advanced modeling techniques like AR, VR and others.

Background

A Digital Twin is a

model of a physical entity that is developed and maintained throughout its lifecycle, from concept, to development, production, operation and decommissioning. The model is continuously updated to reflect the current state of the entity, and as a result, it offers many opportunities to analyse and improve business decision-making.

In modern Digital Twin development, simulation software integrates a suite of technologies, such as photo-realistic simulators and artificial intelligence, to generate predictive models that can be deployed on a broad operational system. The development workflow resembles that of a model-based design framework due to the need for system integration, V&V and deployment. Hence, when we designed the course

Digital Twins: Enhancing Model-based Design with AR, VR, and MR (Online) at the University of Oxford, we considered the disruptive nature of emerging technologies for the digital twin and their impact on industrial model-based design.

This blog post explains our rationale for this course, implications for industry, and techniques to implement these ideas in MATLAB.

The evolution of model-based design

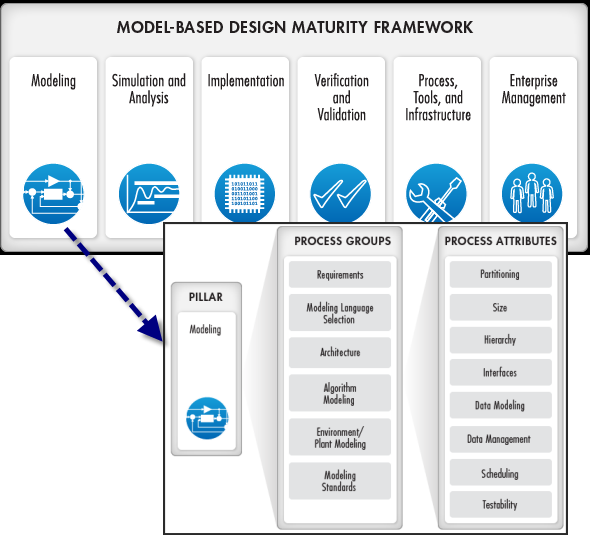

The ideas behind

Model-based design are already mature. The Model-based design approach places virtual models at the centre of the development process to improve the delivery of engineered products. Model-based design (MBD) combines

the concepts of modelling and

automation to

- accelerate the exploration of new designs and perform fast, repeatable tests with modelling and simulation;

- eliminate manual steps and reduce human error by automating steps such as reporting, coding, and verification;

- create a digital thread with traceability from requirements and system architecture to component design and tests;

- perform predictive maintenance, detect faults, and optimize the system in operation using models as digital twins.

These ideas already add many benefits to the current design process, but MBD is evolving in a few directions.

- Digital Twins are becoming a crucial part of MBD as companies seek to continuously improve product versions by analysing complete lifecycles;

- Simulations & Simulators with physics-based engines accelerate modelling workflows. Developers less frequently specify model behaviour, but rather assemble systems as a network of parametric components with prescribed physical behaviour - as in a Simscape model, in a CAD package or in a gaming engine;

- Workflows span many domains and verticals, where technologies are shared across industries, e.g. LiDAR-based mapping in automotive and in construction.

- Model granularity in each vertical is increasing, and components need to be represented at different levels of fidelity to support system-level performance optimisation;

- AI strategies complement modelling, design and analysis (explained below)

- Augmented, Virtual and Mixed Reality enhance capabilities to design engineering products, to test them against virtual scenarios, and to deliver new product experiences;

- Computational Additive & Destructive manufacturing techniques, such as 3D printing and CNC milling, become part of the design process.

Broadly, these ideas come under implementing

Industry 4.0,

i.e. the automation of traditional manufacturing and industrial practices using software and internet technology.

Implications for industry – Digital twins and Model-based design

The evolution of MBD has several implications. Here we will outline some of the impact on industry

1) Impact of AI and algorithms on digital twins

A range of modelling algorithms could be used for Digital Twin development. For example, algorithms that implement

- Physics-based modelling, where a developer implements the governing equations of a physical system and solves them via a combination of analytical and numerical techniques, g. Runge-Kutta solvers for ordinary differential equations, or Finite-Element methods for partial differential equations. Fidelity of the models can be improved with parameter-based estimation from hardware data. The models can also be used to support observers in a system, e.g. Kalman estimators.

- Data-driven modelling, where models are deduced from input-output component data, g. using regressions, look-up tables, or system identification techniques;

- AI-based modelling, in which learning techniques are used to improve the fidelity and dynamic performance of data-driven surrogate models.

A diverse set of skills and expertise are needed by developers to decide which approach is best suited to a given design scenario.

2) Digital twins – unifying the model-based design flow

Digital twins help better inform design and operation stages:

- System Requirements, Functionality and Architectures, are improved on from previous product iterations.

- Subcomponent model development is accelerated by data collected from the field. Using historical data can also reduce risk of plant-model mismatch.

- Integration & Testing – model-based scenarios and scenes allow for broader testing and more robust designs, especially in cases that are expensive to reproduce, g. faults,

- Operations and Sustainment – mismatches between the Digital Twin and the physical asset inform decisions for operation and maintenance.

Tracing the lifecycle of the assets requires expertise in multiple domains, e.g. cloud & edge and integration tools like MATLAB & Simulink that can bring together many technologies.

3) Use of Augmented and Virtual Reality in MBD

Digital twins can support traditional development workflows, but in a broader sense, they have also evolved the way developers

- design with CAD and CAM

- collaborate in design

- deploy a component in an ecosystem and visualize of the ecosystem

- model an ecosystem over time

- automatically generate components, e.g. using optimisation and AI,

All these operations can be enhanced by Augmented or Virtual Reality technologies and many industries are interested in exploring how they can enhance the way they work.

4) New Applications and services based on digital twins

Digital twins could also lay the foundations for new applications and services – for example, for

- Design Optimization

- Verification and Validation

- Mixing Virtual and Real

- Virtual Commissioning

- Fault Detection, Diagnostics, and Prognosis

- Predictive Maintenance

- Operation Optimization

5) System complexity

These emerging technologies are impacting many industries, especially large enterprises where products are composed of many technologies. Components are deployed in often unknown and dynamic environments where diverse factors must be understood and visualised.

Strategies for implementing in MATLAB

In the course, we explore how MATLAB & Simulink support:

- development, analysis and optimisation of designs;

- physics-based model development and synthetic data generation;

- data-driven model development using AI;

- interoperability with 3D simulators;

- deployment to cloud & edge.

Conclusion

When we designed the course

Digital Twins: Enhancing Model-based Design with AR, VR, and MR (Online), we were aware that this is a pioneering course – in an area that is dynamic and rapidly evolving – but has significant potential in many areas. Have a comment for us? Please, leave a comment below!

Cleve’s Corner: Cleve Moler on Mathematics and Computing

Cleve’s Corner: Cleve Moler on Mathematics and Computing The MATLAB Blog

The MATLAB Blog Guy on Simulink

Guy on Simulink MATLAB Community

MATLAB Community Artificial Intelligence

Artificial Intelligence Developer Zone

Developer Zone Stuart’s MATLAB Videos

Stuart’s MATLAB Videos Behind the Headlines

Behind the Headlines File Exchange Pick of the Week

File Exchange Pick of the Week Hans on IoT

Hans on IoT Student Lounge

Student Lounge MATLAB ユーザーコミュニティー

MATLAB ユーザーコミュニティー Startups, Accelerators, & Entrepreneurs

Startups, Accelerators, & Entrepreneurs Autonomous Systems

Autonomous Systems Quantitative Finance

Quantitative Finance MATLAB Graphics and App Building

MATLAB Graphics and App Building

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.