The Slovak University of Technology Fosters Project-Based Learning Using ThingSpeak in Industrial IoT Course

“MATLAB and ThingSpeak extended tools necessary for remote learning and technologies covered by our course. Project-based learning benefited from MathWorks’ high-level programming, simulation, and IoT platform,” Dr. Martin Ernek, Slovak University of Technology

The Slovak University of Technology is the largest technical university in the Slovak Republic and they belong to MathWorks’s Campus Wide License model – along with more than 2000 universities worldwide. The university has almost 11, 000 students and offers education in technical fields and involves students in research in natural sciences, computer sciences, construction, architecture, materials technologies, chemistry, and food technologies.

The Institute of Robotics and Cybernetics at the Slovak University of Technology recently extended its curriculum with a course in Industrial IoT. In this course, the students can learn current communication standards that include OPC UA, CAN BUS, EtherCAT, PROFINET, and technologies that include internet-of-things solutions for primarily industrial applications. Learning in the course is project based, and students must do five projects during the semester. Each project builds on the skills and technologies learned in the previous projects, and the difficulty and complexity of the projects rise with time.

“Students at the Institute of Robotics and Cybernetics use MathWorks products in several courses from Systems Theory to several Control courses. As a standard simulation and development tool, MATLAB enables students to focus more on the topics. MATLAB products offer solutions for technologies used in many industries,” says Dr. Ernek

Challenge

Teaching industrial communication standards and technologies is best done with project-based learning. However, project-based learning requires cooperation between software and hardware. Dr. Ernek explains that, “Due to the pandemic, we were forced to convert the Industrial IoT course into a remote learning experience.” The first challenge was replacing laboratory hardware with models that represent real-world processes like heating systems or assembly lines. “Although PLC manufacturers provide simulators for controllers, we still needed to simulate other laboratory hardware.”

The second challenge was to find a reliable IoT platform. Historical process data are usually captured and stored for later analysis. “Storage and visualization of the process data were one of the key topics of the course. We needed a platform that is easily accessible without a complicated setup for the students,” says Dr. Ernek. Setting up a local IoT platform could lead to complications with databases or communication. Cloud IoT platform seemed like a better option, but it had to be easily accessible via other software solutions used in the course.

The last challenge was to show industrial communication between an operator, who monitors the process, and a remote controller. “OPC UA technology is a well known industrial communication standard used by many industries. Therefore, we needed software that could act as an OPC client,” says Dr. Mrafko. In addition, OPC UA technology is only one of many industrial communication standards, and it would be beneficial to work with or simulate other communication technologies.

Solution

The Slovak University of Technology acquired a Campus-Wide License for MATLAB, Simulink, and related products a few years before the pandemic. The Campus-Wide License gave students, professors, and researchers freedom to access software downloads, online training, and other resources. Moreover, students were familiar with MATLAB and Simulink from other fundamental classes. Therefore, the transition to the Industrial IoT course was seamless. “Having well-known software was beneficial to our course because students did not have to spend a few weeks to learn a new tool,” says Dr. Ernek.

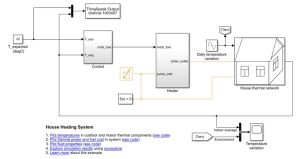

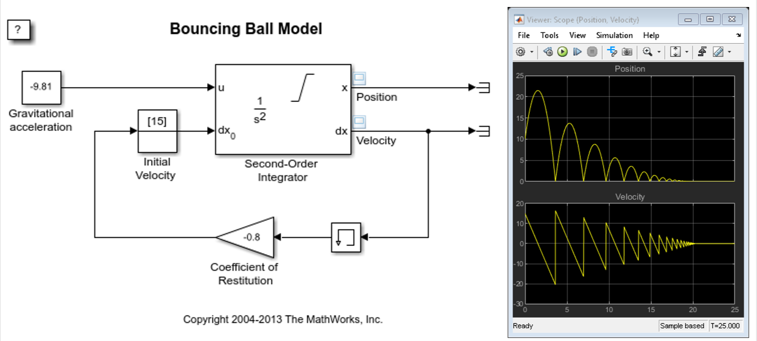

MATLAB, Simulink, and related products were crucial to overcoming the first challenge of representing real-world hardware. Simulation models replaced laboratory hardware. Simulation of a simple system and data transfer to the IoT platform is one of the tasks in the first weeks of the course. “MATLAB offers a plethora of ready-to-use and well-documented examples that we were able to reuse for the course needs,” says Dr. Ernek. For example, the Simscape Fluids House Heating System example was chosen as since it is relatable and easy to conceptualize. Another project uses a custom manufacturing system modeled in Simulink and visualized via Simulink 3D Animation.

Figure 1 Simulink house heating system model adapted to store data in ThingSpeak.

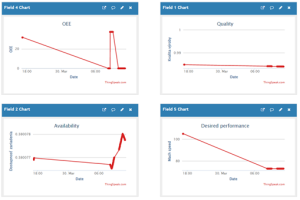

The ThingSpeak IoT platform provided the solution to the second challenge. “ThingSpeak offers data aggregation and visualization and data analysis tools as well. It is accessible via a MathWorks account, easily set up, and works with MATLAB. It was what we needed for our students,” says Dr. Ernek. The House Heating System model was paced to run in soft real-time, and data were sent to ThingSpeak every 30 seconds. The obtained data were then visualized in ThingSpeak, and the student immediately saw if the data had been sent correctly .

Figure 2 ThingSpeak plots output from home heating model. Fluctuation about the set point and the model response for a change in setpoint are seen in the plots.

Projects in the second half of the course require OPC UA communication. Industrial Communication Toolbox provides the capability to read, write, and log OPC UA data from MATLAB and Simulink. In addition, students can write their Apps for reading and writing OPC UA data using the MATLAB App Designer and the simulated OPC UA C++ Demo Server application. The next project focuses on monitoring manufacturing productivity indicators for data obtained from a simulation of packing machines. Students use Node-Red to read data from PLC, process the data, calculate the productivity indicators, and then publish the calculated indicators to ThingSpeak. The last project used the Simulink model, Siemens virtual PLC for control, and an OPC client to read data from a PLC.

Figure 3 ThingSpeak charts for Simulink model outputs from PLC control read via OPC client.

Course evaluations showed that students liked working with new technologies and projects. “The lectures gave us a good introduction to the theory and technologies, which we then applied in the projects. The project was progressively complex and used combinations of real-world technologies,” wrote one of the students. Dr. Ernek and Dr. Mrafko want to continue using MATLAB and ThingSpeak even after returning to the state before the pandemic.

Results

Universal Platform Facilitates Higher Quality Learning Experiences. “All university members and students have full access to MATLAB, Simulink, and various toolboxes with Campus-Wide License,” says Dr. Ernek. “Access to MathWorks tools provided universal software platform for multiple courses across study domains that can build on top of each other.”

Reconfiguration of multidisciplinary projects is simplified. “MATLAB enabled us to quickly convert from laboratory hardware projects to a remote learning experience,” says Dr. Ernek. “Many industry standards are implemented in the MathWorks products family, which allowed students to use them right away and focus on the projects,” notes Dr. Mrafko

Adoption of cloud platform for live data sharing and visualization. “ThingSpeak provided a complete IoT analytics platform in the cloud that is easily accessible to students without additional installations,” says Dr. Ernek. “Ability to visualize and analyze live data was great, but best ThingSpeak feature is seamless cooperation with MATLAB, Simulink, and other products used in our course.”

Products Used

• MATLAB

• Simulink

• Simscape

• Simscape Fluids

• Industrial Communication Toolbox

• Simulink 3D Animation

• ThingSpeak

Cleve’s Corner: Cleve Moler on Mathematics and Computing

Cleve’s Corner: Cleve Moler on Mathematics and Computing The MATLAB Blog

The MATLAB Blog Guy on Simulink

Guy on Simulink MATLAB Community

MATLAB Community Artificial Intelligence

Artificial Intelligence Developer Zone

Developer Zone Stuart’s MATLAB Videos

Stuart’s MATLAB Videos Behind the Headlines

Behind the Headlines File Exchange Pick of the Week

File Exchange Pick of the Week Hans on IoT

Hans on IoT Student Lounge

Student Lounge MATLAB ユーザーコミュニティー

MATLAB ユーザーコミュニティー Startups, Accelerators, & Entrepreneurs

Startups, Accelerators, & Entrepreneurs Autonomous Systems

Autonomous Systems Quantitative Finance

Quantitative Finance MATLAB Graphics and App Building

MATLAB Graphics and App Building

コメント

コメントを残すには、ここ をクリックして MathWorks アカウントにサインインするか新しい MathWorks アカウントを作成します。