Driving Innovation: Simulink Student Challenge 2022 Winner’s Hub Motor Hybrid Vehicle Design

In today’s post, Manjunath speaks with Meng Zhang, the winner of the Simulink Student Challenge 2022. Throughout their conversation, Meng shares his insights and experiences regarding his participation in the challenge, the inspiration behind his project idea, the design challenges he faced, and the results of his simulations and testing. Read on!

Manjunath:Hi Meng Zhang, thanks for taking the time to chat with me today. Could you tell me a bit about why you decided to participate in the Simulink Student Challenge?

Meng Zhang: Of course, happy to interact! I decided to participate in the Simulink Student Challenge for a few reasons. Firstly, I was drawn to the reputation of MathWorks as a company that provides excellent research and development tools for scientists, engineers, industry experts, and students.

Another reason was the productivity brought by MATLAB/Simulink products. As an engineer working in the automotive industry, I find that these tools are essential for exploring various problems related to vehicle performance analysis and traffic planning, as well as signal processing and analysis.

Also, I had some personal reasons for participating. My father was an engineer who used to make manual drawings and calculations by hand using pencils and paper. I call this the “engineering romance of the last century”. For me and many contemporary engineers, the use of MATLAB/Simulink represents a more efficient and accurate way to do calculations, design, and development.

Manjunath: That’s interesting, Meng. So how did you come up with your project idea for the challenge?

Meng Zhang: Well, as you know, with the advancement of vehicle technology, electric motors are becoming more and more prevalent in new energy vehicles. But the traditional central motor drive technology, which uses clutch, transmission, drive shaft, differential, and transfer, has a lot of issues. It adds a lot of weight to the vehicle, requires frequent maintenance, and reduces efficiency. So, I started thinking about alternative solutions.

The hub motor, which embeds the motor in the wheel, eliminates the need for many transmission components and simplifies the vehicle structure. It also allows for a variety of complex driving modes, such as differential steering and even in-place steering through control logic design.

With four-wheel independent speed and torque control, combined with ABS and ESP, it can dramatically increase handling stability during high-speed driving conditions. And imagine a vehicle with this capability, combined with assisted driving technologies like autonomous parking, could easily achieve precise parking under narrow or crowded streets.

Manjunath: That’s truly innovative. So, how did you go about designing this four-wheel drive hub motor hybrid vehicle?

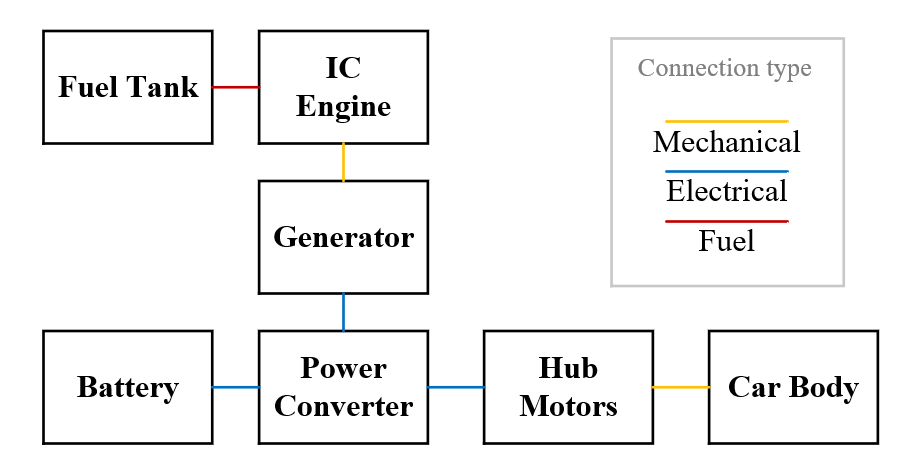

Meng Zhang: To provide you with an overview of the Simulink model, it involved rapid prototyping of a hub-electric hybrid with four-wheel drive. The main focus of the model was to analyse the power performance and energy consumption of the hybrid electric vehicle, and we also introduced solar energy as an auxiliary energy source.

Fig.1 Model principle

Manjunath: That’s interesting. Can you tell me more about the physical processes involved in the model and give an overview of your modelling approach?

Meng Zhang: Sure. The main physical processes involved were battery providing electric power to the hub motors, braking efficiency recovery, mechanical energy outputted by internal combustion engine to electrical energy conversion, solar energy storage, and mechanical energy provided by motors to drive the vehicle. The control process involved was mainly distributed drive of four wheels and adaptive adjustment of hybrid ratio.

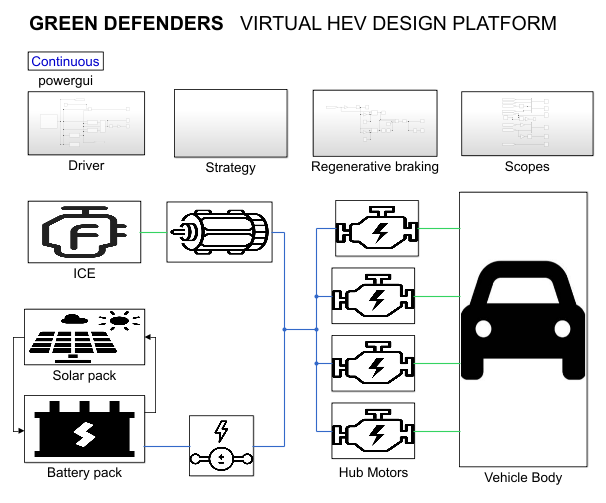

Fig.2 Main simulation interface

We adopted the modelling method combining Simulink and Simscape, where the transfer function and physical characteristics of the system are modelled at the same time, so as to realize the real-time observation of the parameters in the running test process of the hybrid vehicle.

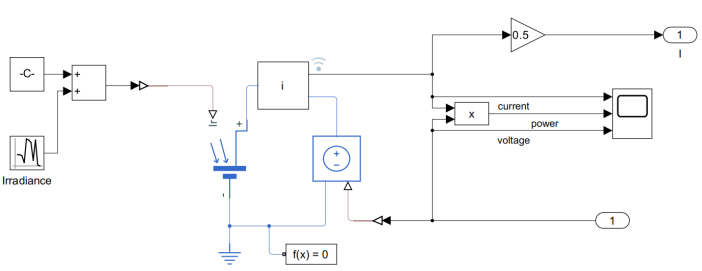

Fig.3 Simulink/Simscape synchronous hybrid modeling approach(“solar pack” module as an example)

We also provided a design platform that can be customized for the user to adjust the parameters of the motor, battery, and other assembled components according to their actual needs.

Manjunath: Your summary of the model is helpful. Now, I’m curious about the conclusion and would like more information about the results.

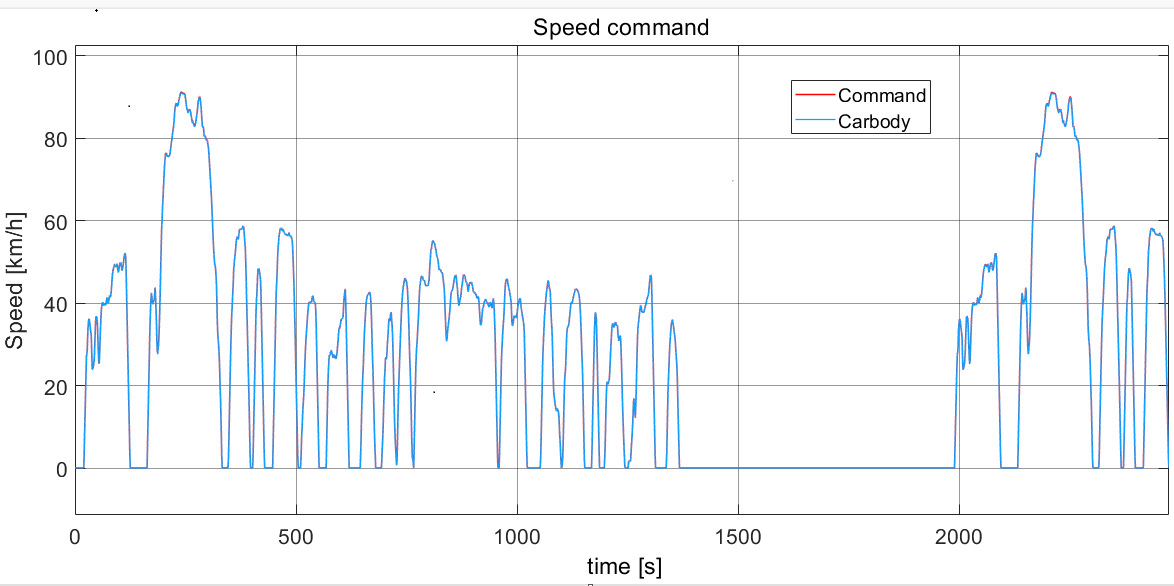

Meng Zhang: We conducted tests on the model using the FTP-75 Drive Cycle and discovered that the simulated velocity closely matched the drive cycle we had chosen. This outcome demonstrated the successful performance of the speed controller.

Fig.4Comparison of obtained velocity with the chosen drive cycle.

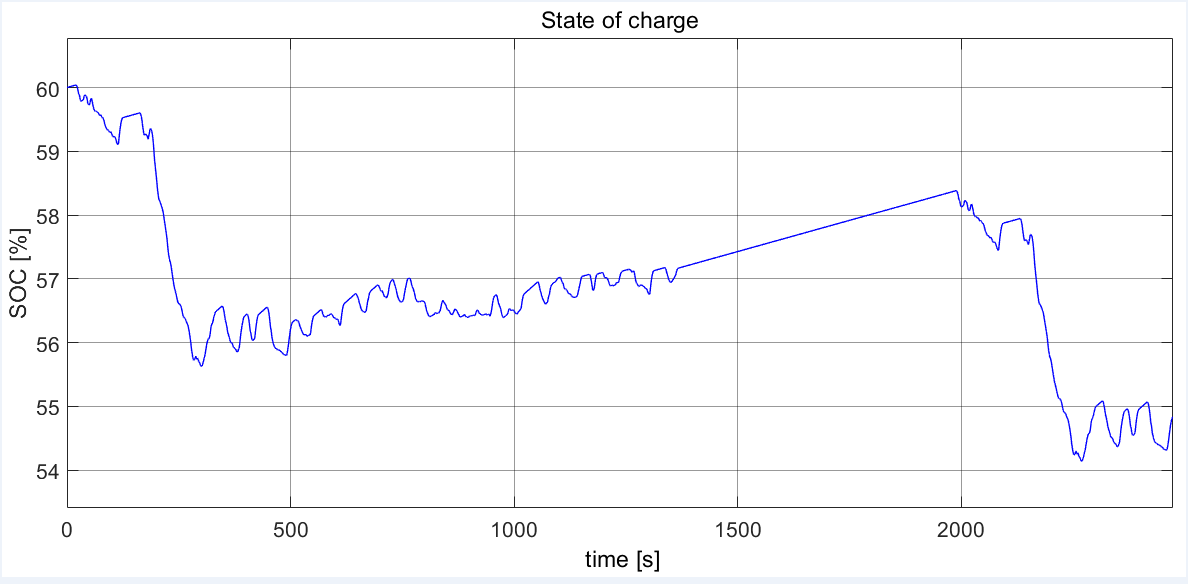

Further, the SOC of the battery was relatively stable during the test drive cycle.

Fig. 5 Battery SOC

Finally, we integrated the model with the Unreal Engine using the Vehicle Dynamics Blockset to visualize the cars behaviour.

Fig.6 Visualization of performance test based on Unreal Engine

For a detailed explanation of the model and results, I would point the readers to the YouTube video that I submitted for this challenge: https://youtu.be/gWoS1ZL13gE

Manjunath: Were there any challenges that you faced during the design process? If yes, how did you address it?

Meng Zhang:One of the primary challenges we faced was selecting the appropriate components while aligning with the current market supply conditions. It was crucial for us to strike a balance between meeting our design targets and controlling overall costs.We had to avoid excessive redundancy to prevent increased costs, size, and mass, while ensuring the components met the actual needs of the system.

To tackle this, we conducted extensive market research and utilized product data for our models. Real-time monitoring of parameters such as peak current, voltage, and temperature helped validate our component choices.The simulation capabilities of Simscape facilitated the quick development of temperature monitoring models for the battery and motor, ensuring their accuracy.

Overall, by integrating market research, product data, and simulation techniques, we successfully addressed the component selection challenge while considering cost factors.

Manjunath: That’s fascinating! Thank you for sharing your insights and congratulations on winning the Simulink Student Challenge 2022.

Meng Zhang: Thank you! I’d like to offer some advice to future participants. I would recommend focussing on innovation and leverage the versatility of Simulink’s extensive library of blocks and toolboxes. Experiment with various components, algorithms, and simulation parameters to optimizethe design. Ensure that your simulations accurately reflect the system’s behaviour and performance by validating against established benchmarks, empirical data, or theoretical analyses. Lastly, create a concise and captivating video that effectively communicates your project’s objectives, methodology, and outcomes.

Manjunath: Thank you for providing such valuable advice for all future participants of the competition.

Dear readers, the Simulink Student Challenge is an incredible opportunity for learning and growth. Embrace this experience as a chance to enhance your skills, broaden your knowledge, and gain practical insights into system design and simulation.

To learn more and participate in the upcoming competition, visit: Mathworks.com/studentchallenge

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.