Turning Ideas into Aircraft: Conceptual Design with MATLAB Live Scripts

Today’s guest blogger is Khushin Lakhara, who is on the Student Programs team at MathWorks supporting aerospace competitions. Over to you, Khushin!

Table of Contents

- Introduction

- Collecting requirements

- Evaluating design parameters with Sensitivity Analysis

- Selecting configuration

- Dimensioning components and their placements

- Component placement with the Aircraft Intuitive Design App

- Evaluating aircraft performance with Aircraft Performance Analyzer (APA) Live Task

- Conclusion

Introduction

Conceptual aircraft design is the very first phase of the aircraft design that converts requirements into conceptual design, where configurations are selected, and dimensions are estimated. Based on the dimensions and configurations, multiple solution designs are generated. These solutions need to be compared before deciding on specific details, and optimizing the design in the detailed aircraft design phase.

Figure 1: Conceptual aircraft design phase

- Collecting requirements

- Evaluating design parameters with Sensitivity Analysis

- Selecting configuration

- Component sizing and their placement

- Evaluating Performance

Figure 2: Step by step process in the Conceptual aircraft design phase

Let us dive deep into these steps and explore how MATLAB can help you convert your requirements into a conceptual aircraft design solution.

Collecting requirements

The conceptual aircraft design phase starts with requirements. These requirements are provided by either the customer in commercial cases or by the competition organizers in student competitions. These requirements may include desired performance specifications such as maximum speed, payload capacity, max ground roll for takeoff and landing, climb speed, etc.

Sometimes these requirements might appear contradictory, but governed by an overall objective, such as the cost of the vehicle or flight score in a competition. For example, consider the AIAA DBF 2021 competition problem statement, which required a heavier payload but a faster aircraft.

These contradictory requirements need to be understood and traded off to comprehend their impact on each other and the overall objective. This is why we need sensitivity analysis and trade-off studies before converting them into a design solution.

Evaluating design parameters with Sensitivity Analysis

Aircraft design is a tradeoff between requirements and overall objective (cost or flight score, or performance). Imagine you are tasked with designing an aircraft with a given payload capacity and max speed, but with a constrained wing span. It is quite probable that changing one of the given requirements may bring a significant difference in the objective, i.e., flight score.

Hence, it becomes crucial to understand how sensitive the objective function is to each requirement. For this purpose, engineers and scientists use a method called Sensitivity Analysis (SA) to understand the impact of the change in each requirement on the objective function and accordingly trade off their requirements.

The blog on Sensitivity Analysis with MATLAB for Student Competitions presents how SA can be used for aircraft design. It presents the AIAA Design Build Fly Competition 2021 as a case study with the univariate sensitivity analysis method. This blog discusses how various design parameters are sensitive to design objective and how their choice suggests different aircraft configurations.

This blog is also supplemented by a video on Sensitivity Analysis with MATLAB for Student Competitions and a File Exchange entry where you can download the code and play with it.

Based on the sensitivity of the requirements, the aircraft designer finds an appropriate range of design requirements and accordingly trades off the desired aircraft specifications with customers. Once the requirements are frozen, designers move to the next task, to explore the appropriate configuration and dimensions of the aircraft.

Selecting configuration

As soon as requirements are formalized aircraft designers perform engineering research to understand existing designs, materials, and technologies. Designers may find multiple solution configurations that need to be compared based on multiple factors, including performance, weight, aerodynamic efficiency, material availability, manufacturability, and ease of maintenance.

Designers use various methods to compare and select configurations for various components as well, such as high wing or low wing, electric propulsion or combustion-based propulsion, T-tail, or V-tail, etc.

Figure 3: Aircraft configuration selection based on the Figure of Merits method

Dimensioning components and their placements

As soon as the configuration is selected , it is time to change the design requirements into aircraft dimensions. This process starts with converting multiple design requirements into a few meaningful numbers and using them to calculate the appropriate dimensions.

Aircraft designers use a method called Constraint Analysis (CA) for this purpose. It helps to estimate initial dimensions such as wing planform area and power/thrust required. Based on these initial dimensions, the sizing and placement of other components are calculated. These dimensions and placements are iteratively calculated till the design meets the given requirements. Converting requirements into initial dimensions with Constraint Analysis Live Task

Constraint Analysis involves mapping various design requirements as constraints on a plot between the Power to Weight ratio (P/W) or Thrust to Weight ratio (T/W) and Wing Loading (W/S), i.e. Aircraft Gross Weight (W) divided by wing planform area (S). The area overlapped by these constraints is known as a feasible design space.

Figure 4: Converting design requirements into a feasible design space

Aircraft designers can easily evaluate this feasible design space with the Constraint Analysis Live Task. This Live task can evaluate the design space based on multiple constraints, including landing ground roll, take-off ground roll, climb speed, maximum cruise speed, etc. It provides both graphical and numerical results for further use in analysis. This live task can also be changed into code and used for customizing the analysis.

Figure 5: Constraint Analysis (CA) live task in MATLAB

Once the feasible design space is evaluated, a design point is selected (in terms of (P/W) or (T/W) ratio and wing loading (W/S). Based on the initial estimate of aircraft weight (W) with

- Wing loading (W/S), the required wing planform area (S) can be calculated.

- (P/W) or (T/W) ratio, the required power and thrust can be calculated. These specifications are used to select a power plant.

Based on these initial parameters, wing sizing and selected power plant thrust or power, other component sizes can be calculated.

More details and an explanation on this live task can be found on the File Exchange repository and in a detailed video, where you can download and learn more about using this live task for your conceptual aircraft design.

Component placement with the Aircraft Intuitive Design App

For the selected wing area and power plant, the sizes and location of other components can be calculated. These are governed by two factors: aerodynamics and stability. Any change in these factors brings a domino effect on aircraft design and can lead to a completely different design.

Playing with these factors can be benefitted from an interactive tool that can enable designers to rapidly prototype and immediately visualize their effects. The Aircraft Intuitive Design (AID) app in MATLAB offers such an environment where you can visualize the impact of change in size or location on aerodynamics and static stability.

In addition to built-in, linearized stability approximations, the app also interfaces with multiple software, including Digital DATCOM, Tornado (Vortex Lattice Method), and AVL (Athena Vortex Lattice Method), for more advanced analysis.

Figure 6: Rapid Prototyping with Aircraft Intuitive Design App

Want to learn more about how AID can help you in your aircraft design journey? Check out this video where Zachary Lietzau, the creator of the app, explains how it helped them in their AIAA DBF competition journey.

Evaluating aircraft performance with Aircraft Performance Analyzer (APA) Live Task

Once a conceptual design is ready with its dimensions, it is important to assess if this design meets the requirements given by customers or competition organizers. Although constraint analysis helped us to convert requirements into meaningful numbers and find a feasible design space that will meet requirements, depending on the choice of design points in the feasible design space, the overall performance may vary significantly.

At this point, we may also have multiple design solutions. Hence, it becomes crucial to estimate the performance of a given design. Finally, based on the performance parameters and objective function, one conceptual design is finalized to be further detailed and optimized.

Figure 7: Need for analyzing aircraft performance and comparing various aircraft design

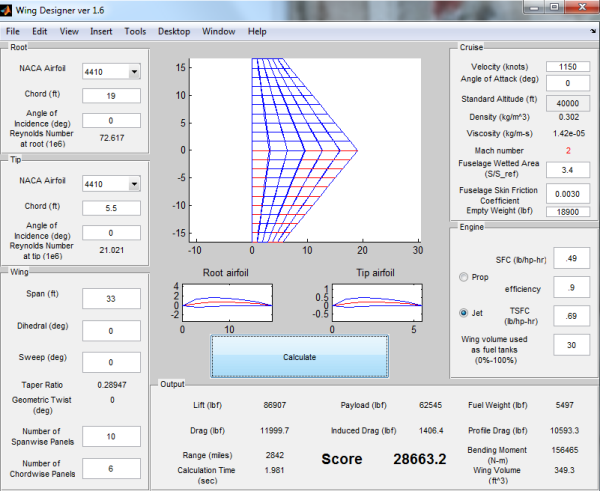

For this purpose, the Aircraft Performance Analyzer (APA) Live Task in MATLAB helps you to estimate the various performance parameters, including the take-off, landing, range, endurance, power required, and power available at various speeds, etc. It provides results both in numerical and graphical form, ready to include in aircraft design reports.

It also provides Aero. FixedWing object, which can be further used for stability analysis and linear plant model development for simulations. Also, it can be converted into code to customize and automate the analysis of a batch of conceptual designs.

Figure 8: Aircraft Performance Analyzer Live Task in the MATLAB

Curious about learning more about the APA Live Task? Download the File Exchange repository and check out this video, and learn how the APA live task helps you to quickly estimate the aircraft performance and finalize a conceptual design.

Conclusion

In this blog, we explored the conceptual aircraft design phase and learned about various resources that can help you accelerate your aircraft design journey.

If this blog sparked your interest in aircraft design made you curious about how this conceptual design is further detailed and optimized, or if you have any queries about this blog, please write to us at roboticsarena@mathworks.com. If you are looking for detailed learning resources for aircraft design, do not miss out on checking the Aerospace Learning Resources. This learning path is a collection of videos, documented examples, and file exchange entries to ramp you up for your aircraft design journey.

- Category:

- Live script,

- MATLAB

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.