When the charging station is (only) 93 million miles away

Lightyear has had a great month. First, they announced that their prototype car drives over 440 miles (770 km) on a single charge. And that’s on a battery charge of just 60 kWh.

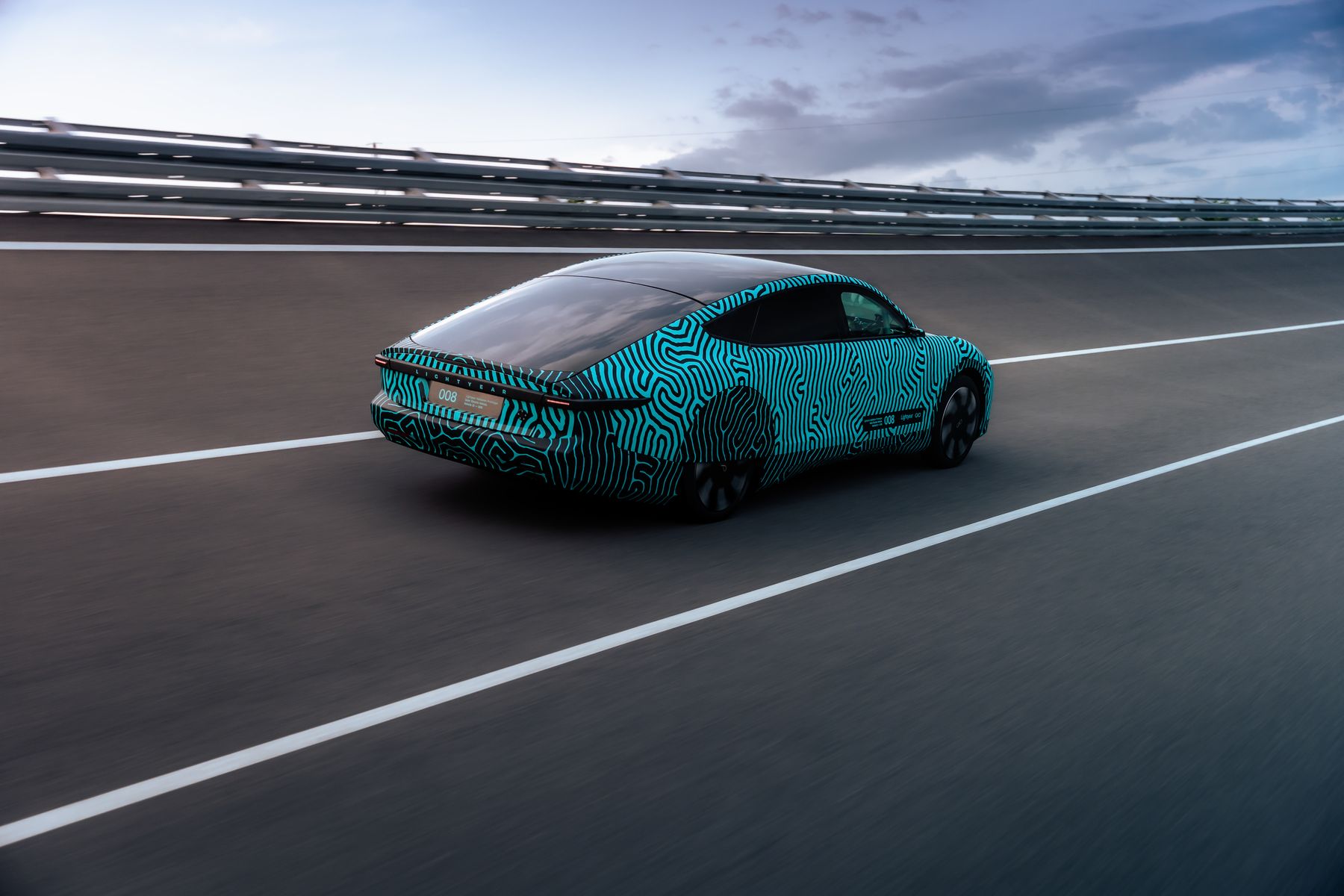

The Lightyear One prototype zipped around the test track with a little help from the big charging station in the sky. This power source is, on average, 93 million miles ( 149.6 million km) from Earth.

“440 miles is a big deal, but the bigger deal is that the Lightyear One did it a relatively small battery pack,” Motortrend reported. “’So what?’ you might be thinking. Lucid and Tesla both have high-dollar, high-range EVs that can crack the 400 mile mark. That’s true, but the Lightyear One did what Tesla and Lucid can do but with a much smaller battery pack.”

And, as Motortrend noted, Lightyear is targeting delivery to its first customers in 2022. This brings us to the second splash of news from Lightyear. Lightyear has partnered with a manufacturer to build its solar-powered car. According to The Verge, Lightyear is working with Valmet Automotive, a manufacturer that has built cars for Mercedes-Benz, Saab, and Porsche.

Aerodynamics vs. solar panel surface tradeoff

The key to the range of the Lightyear One has been maximizing solar charging while minimizing air drag.

Lightyear One’s aerodynamic shape adds to the car’s high efficiency. It’s long with a slope that resembles the cross-section of an airplane wing. Other decisions, such as adding wheel covers to the rear tires and replacing side mirrors with cameras, squeezed out even more efficiency. Wind tunnel tests showed that Lightyear One broke the record for being the most aerodynamic five-seater electric car to date.

When considering the car’s roof, they needed to find the right balance between a completely flat, wide shape that would maximize sunlight exposure, and one with curves that would reduce wind resistance. By running simulations in Simulink, they were able to scrutinize these kinds of design tweaks and see where the best tradeoffs were to improve efficiency.

Image credit: Lightyear

From a student competition to a road-ready car

To see how Lightyear got its start from a student competition team, check out the article

Cleve’s Corner: Cleve Moler on Mathematics and Computing

Cleve’s Corner: Cleve Moler on Mathematics and Computing The MATLAB Blog

The MATLAB Blog Guy on Simulink

Guy on Simulink MATLAB Community

MATLAB Community Artificial Intelligence

Artificial Intelligence Developer Zone

Developer Zone Stuart’s MATLAB Videos

Stuart’s MATLAB Videos Behind the Headlines

Behind the Headlines File Exchange Pick of the Week

File Exchange Pick of the Week Hans on IoT

Hans on IoT Student Lounge

Student Lounge MATLAB ユーザーコミュニティー

MATLAB ユーザーコミュニティー Startups, Accelerators, & Entrepreneurs

Startups, Accelerators, & Entrepreneurs Autonomous Systems

Autonomous Systems Quantitative Finance

Quantitative Finance MATLAB Graphics and App Building

MATLAB Graphics and App Building

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.