Using data analytics to reduce food waste

Food waste is a global concern. It greatly affects our environment by releasing greenhouse gases at landfills. It also uses an immense amount of water used to grow food that is ultimately discarded.

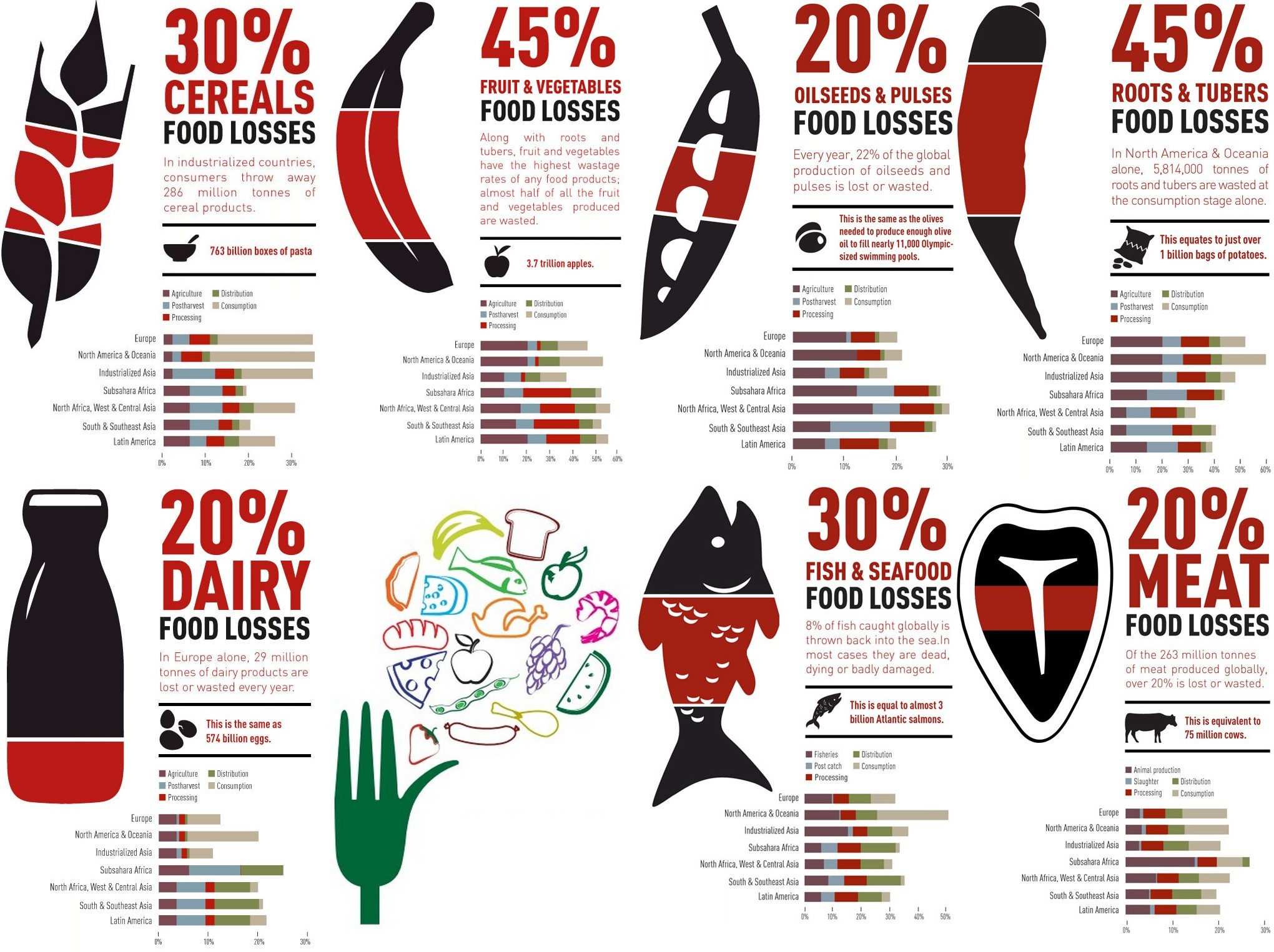

Facts about food waste

- Roughly one-third of the food produced in the world for human consumption every year — approximately 1.3 billion tons — gets lost or wasted. (Food and Agriculture Organization)

- Nearly 95 percent of the discarded food ends up in landfills or combustion facilities. Once in landfills, the food breaks down to produce methane, a potent greenhouse gas which contributes to climate change. (US Environmental Protection Agency)

- Food that is harvested but ultimately lost or wasted results in a tremendous amount of water waste as well. According to Smithsonian.com, throwing out an apple is like pouring 25 gallons of water down the drain, while beef has a water footprint of 1,800 gallons per pound.

Food waste occurs across the entire food system – producers, retailers and restaurants, and consumers – and many sectors are using technology to tackle the issue. For grocers, a reduction in food waste is not only good for the environment, it can be great for their financials. Many grocers are implementing programs to reduce waste, from supply chain management to targeted promotions to sell fresh food before it reaches the “sell-by” date.

One grocer’s approach

According to a new ranking of the supermarkets developed by The Grocer, Tesco is doing the best job at tackling food waste:

Tesco’s “pioneering” approach to food waste in stores and across its supply chain, earned high praise for its transparency, innovation, commitment, and results. “The levels of investment and seriousness with which Tesco are taking this challenge are second to none,” said one expert.

Tesco is taking a multi-pronged approach, including partnering with food distribution charities and marketing aesthetically imperfect fresh vegetables at a reduced cost. They have also taken a data-driven approach to reducing waste across their entire supply chain.

Using data analytics to reduce food waste

Tesco uses a data-driven approach to reduce food waste. Tesco’s systems order 110 million pounds of food every day. So the retailer turned to data analytics to improve the supply chain and reduce food waste. Their systems utilize hundreds of terabytes of observed data from its many store locations to develop, train, and test their algorithms.

Tesco utilizes weather forecasts to more accurately predict how the demand for food will change. Common sense tells you that people buy more salad on warm weekends during the summer. Data tells you exactly how much more salad: 42%. This method helps minimize food waste by ensuring the correct amount of product is available at each location.

The food retailer also developed systems to determine how aggressively to reduce prices on items that are approaching their expiration date. The goal is to sell the products before they reach the expiration date and have to be discarded.

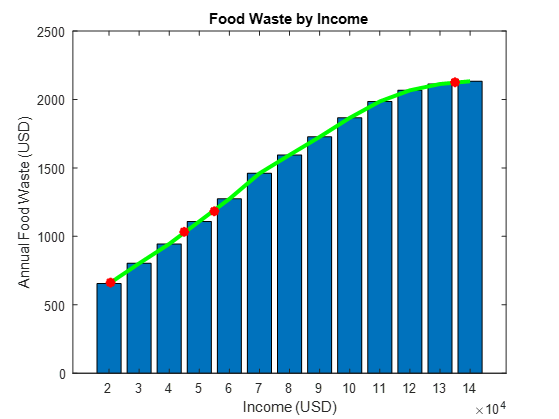

Based on remaining stock and models of product sales rates, MATLAB-based algorithms adjust prices throughout the day in each store. Tesco is using data handling and machine learning to understand and improve the effectiveness of the reductions process.

Price reduction effects vary based on typical product rate sales. This figure shows that the rate uplift is more uniform for fast-selling products. Image credit: Tesco presentation at MATLAB UK Expo.

The proof is in the numbers

It’s one thing to use data to make decisions. It’s another to show the data on your accomplishments. Tesco was the first company to publish its food waste data. With the price reduction system in place, Tesco cut produce waste by 2% last year.

In addition to reducing waste, these initiatives have a positive economic impact for the retailer as well.

According to RetailWeek, “… algorithms built by [Tesco’s] supply chain analytics team create discounts that are transmitted to handheld devices in store, avoiding about £30m of wasted stock a year. Analytics have also been used to improve stock levels at distribution depots, saving about £50m annually.”

Cleve’s Corner: Cleve Moler on Mathematics and Computing

Cleve’s Corner: Cleve Moler on Mathematics and Computing The MATLAB Blog

The MATLAB Blog Guy on Simulink

Guy on Simulink MATLAB Community

MATLAB Community Artificial Intelligence

Artificial Intelligence Developer Zone

Developer Zone Stuart’s MATLAB Videos

Stuart’s MATLAB Videos Behind the Headlines

Behind the Headlines File Exchange Pick of the Week

File Exchange Pick of the Week Hans on IoT

Hans on IoT Student Lounge

Student Lounge MATLAB ユーザーコミュニティー

MATLAB ユーザーコミュニティー Startups, Accelerators, & Entrepreneurs

Startups, Accelerators, & Entrepreneurs Autonomous Systems

Autonomous Systems Quantitative Finance

Quantitative Finance MATLAB Graphics and App Building

MATLAB Graphics and App Building

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.