Cracking the Code: Unique Insights from BEST Robotics Finalists!

For this week’s blog post, we invited a BEST Robotics team to share their journey to becoming a finalist in the 2022 Souths BEST Championship. For the 2022 season, BEST Robotics focused on a global world challenge – improving supply chain! Made2Order was based on the packaging industry and the problems and dangers of human employees fulfilling orders manually. As always if you would like to use MATLAB and Simulink for your robots, please visit our BEST Robotics page or contact us at roboticsarena@mathworks.com. MathWorks is immensely proud of their achievements, and we hope you also find their insights useful! With that, I will hand it over to Allie Maples and Natalie Rische from MACH Robotics.

Introduction

BEST Robotics promotes the interest of students in engineering, science and technology and inspires them to pursue careers in these fields. Our team has been participating in BEST robotics for fourteen years. Our team is composed entirely of homeschooled 6-12th grade students. MACH is a student lead organization; all the leadership roles are voted on by students and previous leaders help in the process of assigning other members to departments.

MACH Robotics Team

Our Robot: Sting

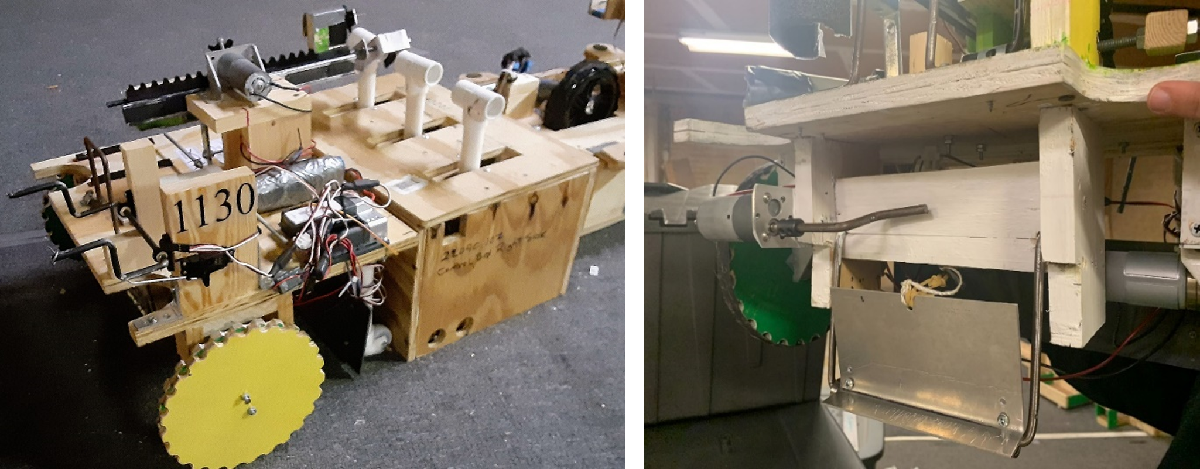

Our robot’s formal name is Autobee, but our engineers lovingly nicknamed it “Sting”. Autobee was the company theme we established to create autonomous technology in keeping with BEST’s 2022 challenge Made2Order. Our task was to build a robot that would control a field robot, named Squeaky, and control Squeaky to fulfill orders.

We will quickly break down some of the most innovative components of our robot.

- Our lever arm system was able to easily switch between two of the levers on the field’s control box at the push of a button, this significantly cut down on run time.

- Our second notable system is the box dolly. This system was able to lift nearly seven pounds, tremendously higher than what was necessary, and made the transportation of the boxes easy for our drivers.

Robot Sting

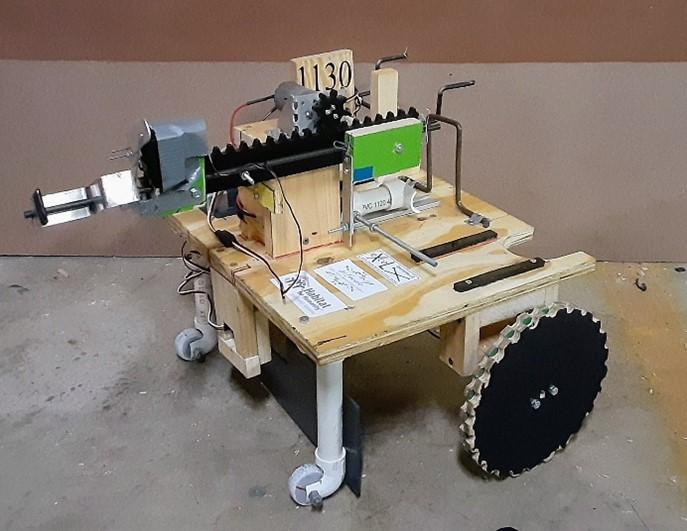

Our Design process

We used a fail-fast version of the five-step engineering design process for all aspects of our robot.

We learnt learned most of our Simulink skills from a previous person who programmed the robot. We also attended multiple MATLAB and Simulink workshops that are held in the summer. We referred to example codes that are provided in the VEX Companion App to help when we were not sure how to program a certain function in Simulink. Our team preferred to use Simulink because of how easy it is and the graphical nature that allows us to visualize code.

Our Code

Our program for the 2022 game was designed to operate a robot that can drive throughout the field, push and pull a control box lever, grab onto the order boxes for relocation, dispense the Squeaky arm, autonomously push and pull the control box lever with little driver input and reprogram the control box on command to allow for only grabbing one lever.

The program for STING was built using the VEX ARM Cortex support package for Simulink. This program included all the different controls for the robot and consists of a control panel and 6 subsystems: Drive Subsystem, Lever Arm and Claw Subsystem, Box Hook Subsystem, Squeaky Arm Dispenser Subsystem, Autonomous Subsystem, and the IR Transmitter Subsystem.

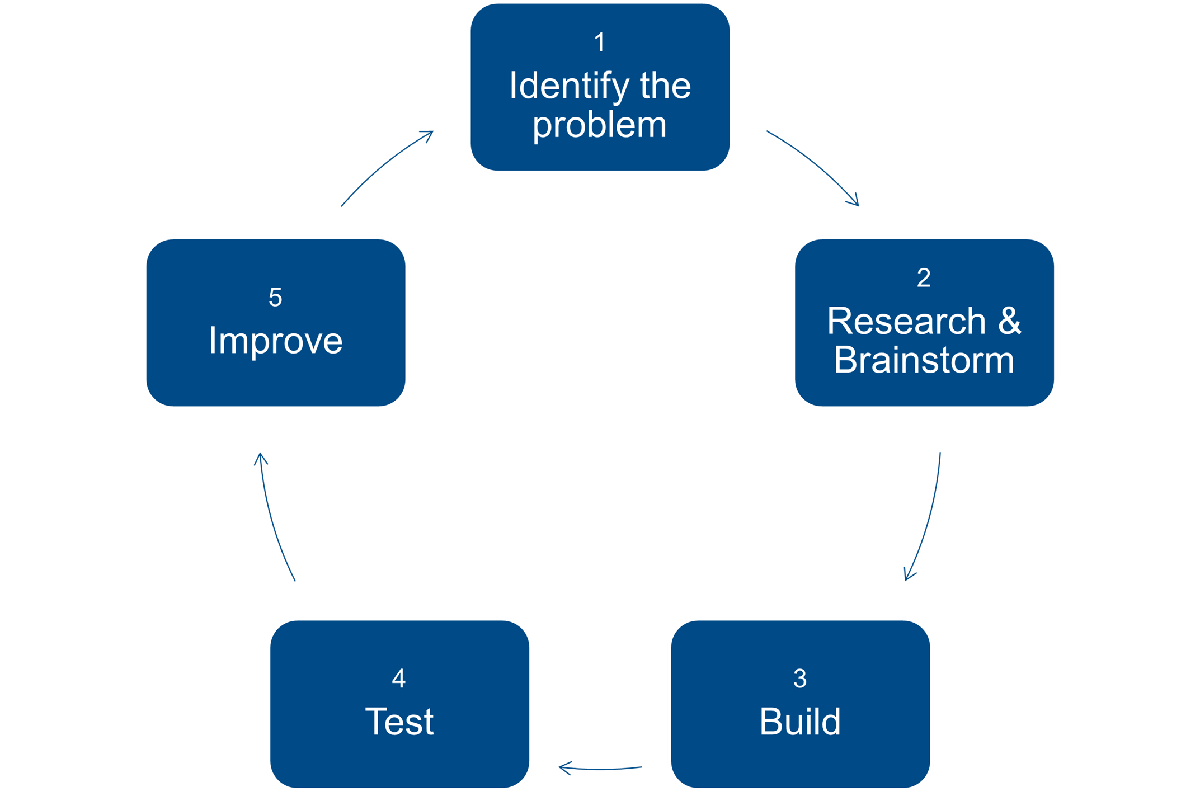

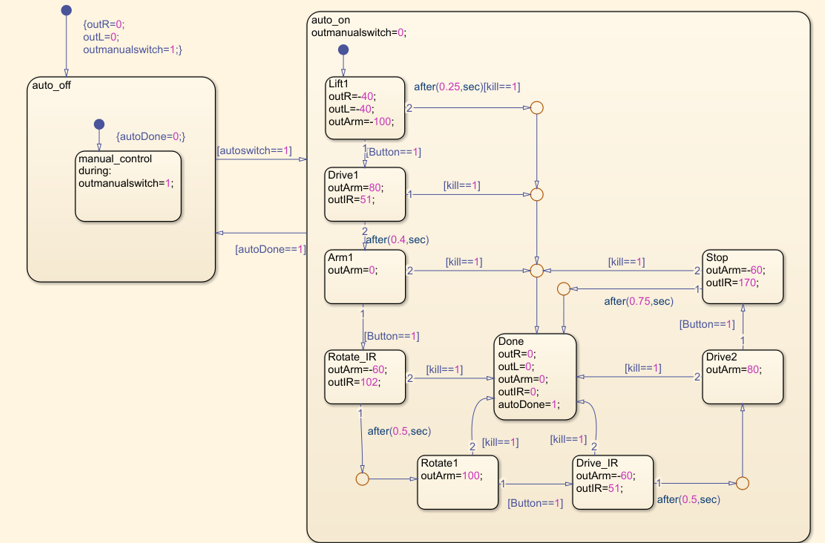

We used Stateflow charts for multiple purposes in our program, but the biggest area we used them was for our autonomous subsystem. The visual nature of Stateflow made it easy to track and debug the various commands used in the autonomous subsystem.

Autonomous Subsystem

Autonomous Stateflow

The autonomous subsystem is a feature that was added to more efficiently control Squeaky. It can reprogram the functions of the levers to raise, rotate, and drive Squeaky. This function was designed to be driver aided. Once in position, the driver would press a button, starting the autonomous system. This cuts out a degree of human and robotic error, allowing for this mode to operate on any field. The program controls the robot while the driver tells it when to move on to the next function.

We decided to include the autonomous subsystem to our program so that we could easily score more points and reduce human error. In an average run, without the assistance of the autonomous system, the driver would score between 263 and 305 out of 488 points, but with the autonomous system we could easily score 347.

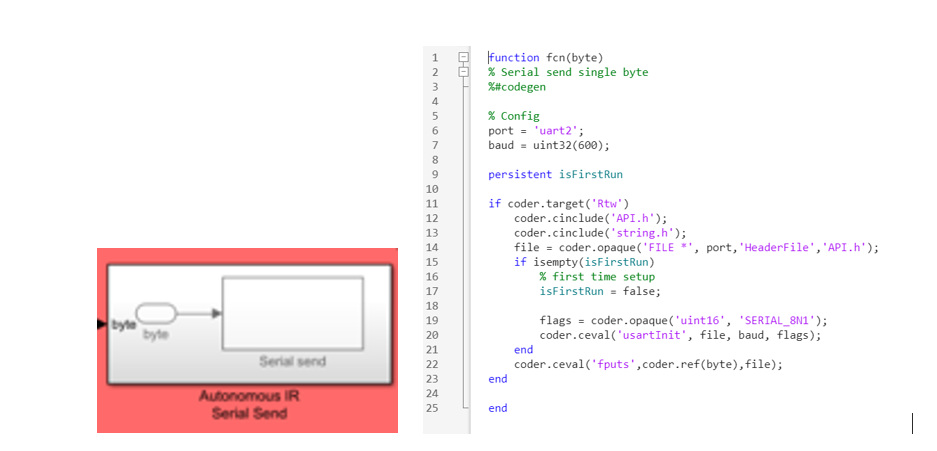

The Autonomous IR Serial send block was the bridge between our robot Sting and the field robot Squeaky. We used an example code from Simulink to allow us to implement this.

Autonomous IR serial send block.

For more information on our full program, check out our video submission for the 2022 Simulink Design Award here.

South’s BEST Regional Championship

Every year MACH competes at the local level. This event determines which teams qualify for the Regional Championship. Last season we participated with Emerald Coast BEST and finished first overall, a nice win for our team. We then placed second overall at the Souths BEST Regional Championship at Auburn University.

As of the 2022 season, MACH had a massive growth of new students as well as a mass departure of experienced members. Our newer team worked incredibly hard to stack up with our competitors, and we couldn’t be prouder of our students.

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.