Modeling Thermal Liquid Systems: Choosing a Water Heater

This week we talk about the new Simscape Thermal Liquid domain introduced in R2013b, and we see how it helped me to analyze how much I pay for hot water in my house.

A Real-Life Problem

Last year I bought a house. For the first time in my life, I have an oil furnace, and a oil-fired storage water heating system. Last summer I was traumatized to hear the furnace starting in the middle of the day when it is 100 degrees Fahrenheit outside and I am not using any hot water.

I thought it would be a good idea to use the Simscape Thermal Liquid domain to analyze if it would be worth changing my current system to something else, for example a tankless system. To help me with that, my colleague Zack Peters offered to put together a few Simulink models.

The Model

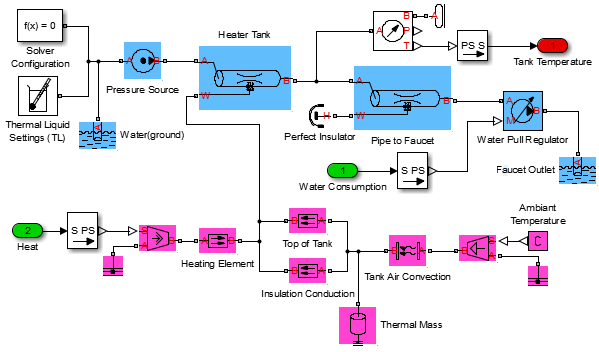

I like using Simscape because you create a model by assembling components the way they are assembled in real life. In the model shown below, the blocks through which the water flows are colored in blue. You can find:

- The town water supply enters my home at a presure of 40 psi at 47 degrees Fahrenheit (represented using the Temperature Reservoir)

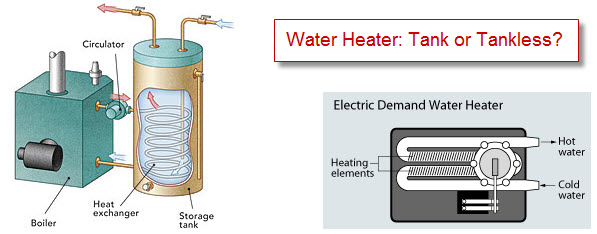

- To model the water heating system, we use the Thermal Liquid Pipe block. In the case of the storage water heater, this pipe is the size of a standard tank. For the tankless system, this same pipe is just one inch in diameter.

- When water exits the heating system, the water goes through 30 feet of pipe.

- At the end, the water reaches a faucet implemented using a Controlled Mass Flow Rate Source letting three gallons of water per minute pass through when open.

To model the heat going in and out of the tank, we used blocks from the Simscape Thermal Domain, highlighted in magenta in the model. You can find:

- On the left, heat is injected in the system using the Ideal Heat Flow Source block. For the oil-fired storage heater, we found is 0.65 Gallons per hour is a reasonable number, which gives 90,000 BTU/hr. For a gas tankless system, we can input up to 157,000 BTU/hr.

- The heat is transferred to the thermal Liquid Pipe through a Conductive Heat Transfer block, which has different dimensions and thermal conductivity for each system.

- Using an Ideal Temperature Source, we model the ambient air, where heat is lost from the tank through Conductive Heat Transfer and Convective Heat Transfer blocks.

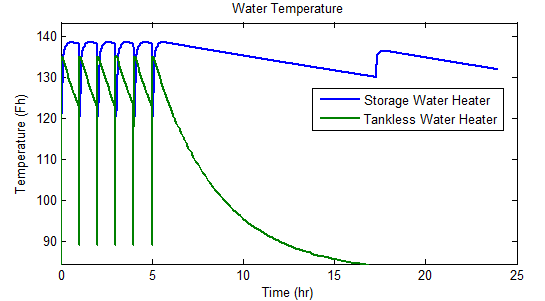

To test the simulation, we used the U.S. Department of energy residential water heater test procedures and standards for which consumer products should be tested against. One test, the 24-Hour Simulated Use Test determines the energy consumed by a water heater over a 24-hour period using a prescribed flow pattern. It requires that 64.3 gallons be drawn over the course of 6 separate draws separated 1 hour apart, followed by approximately 19 hours of no activity. It also specifies that a temperature set point of 135 F should be used.

When I compared the outlet temperatures of both systems, I could see that:

- When opening the faucet, the tankless system outputs colder water for a few seconds, until the heat controller kicks in. I read reviews for these systems describing that exact behavior.

- After a long period without using hot water, the storage system needs to fire up to keep the water in the tank hot. This is exactly what I observe in my house.

If we integrate the energy consumption, we can see that, obviously, the tankless water heater uses less energy. It transfers heat more efficiently and turns on only when hot water is needed. However there is more to tell to this story. The storage water heater is an oil fuel system while the tankless water heater runs off of propane, each of which have different costs per gallon in the market and different energy content stored per gallon.

Taking those numbers into account, we found out that the two systems use nearly the same number of gallons of fuel per day. When multiplied by the current cost of fuel here in New England, we find that the storage water heater costs $\$$2.18 per day while the tankless is only $\$$1.86 per day. That’s a difference of about $\$$116 per year.

Conclusion

I am pretty impressed to see that with just a few Simscape blocks we have been able to obtain numbers very close to the bills I received from my oil provider last summer.

If needed, we could increase the complexity of each component, but for now I think I have enough information to choose the system I need for my house. Now that I have this framework, I will be able to analyze different systems and compare those results to see if the cost/benefits of changing my system is worth it.

Now it's your turn

Download Zack's models for the Storage and Tankless systems, and let us know what you think of the Simscape Thermal Liquid domain by leaving a comment here.

- Category:

- Guest Blogger,

- Physical Modeling,

- What's new?

Comments

To leave a comment, please click here to sign in to your MathWorks Account or create a new one.